Tesla: Ushering In The Age Of Sustainability

Recap of Tesla Investor Day, Tesla has reached escape velocity.

I asked Chat GPT to summarize Tesla Investor Day:

"The speaker shares their experience at Tesla's investor day and factory tour. They were impressed with the efficiency of the factory and the dry electrode battery technology, which they believe is key to Tesla's future success. The dry electrode technology is being continuously improved and automated to reduce costs and increase production speed. The speaker thinks that once this technology is scaled up, it will revolutionize battery manufacturing and production. Overall, they believe Tesla is reinventing the manufacturing process and pushing the envelope in terms of innovation."

Not bad, but in this article, I intend to prove humans are still more capable than A.I. (for now)

Key Takeaways

Here are my key takeaways from Tesla’s nearly 4 hour long Investor Day Presentation. Tesla Investor Day was not only for Tesla stock investors, but anyone who is an inhabitant of Earth.

The main message of today, I really want today to be not just about Tesla investors who own stock but really anyone who is an investor in Earth. What we’re trying to convey is a message of hope and optimism. Optimism that is based on actual physics and real calculations, it is not just wishful thinking, Earth can and will move to a sustainable energy economy, and will do so in your lifetime. - Elon Musk

Tesla is all about continuous improvement and this cannot be emphasized enough. It is how they continue to defy what is possible with not only their products but their production process, which is what will set them apart in the long term. Much of the presentation went into the technical aspects of how this is possible, but simply put it is all about relentless iteration and optimization. This is how they look at everything from the vehicles, to the software, to the production line, to new products and this is how the business continues to move fast and become absurdly efficient. The current plan is to build their next generation vehicle, a cheaper model, with a cost reduction of 50%. At this point only a fool would bet against this coming to fruition and if you think it can’t be done then you have not been paying attention. What follows will explain how they get there.

Culture and Organizational Structure

To make a critical decision we can have the battery cell chemists, the mechanical engineers, the manufacturing engineers, the supply chain team, the automation designers, the software programmers all in one room, working together in real time. And that allows us to make decisions that are best for the whole car and to make them really fast. And that approach is unlike traditional automotive engineering which is really fractured. - Colin Campbell, VP Powertrain Engineering

This quote is indicative of Tesla’s culture, which former Tesla employee Farzad Mesbahi stated is the company’s greatest competitive advantage. Here is a link to part of my interview with him:

Tesla designs the entire car AND the factory that builds it, whereas traditional car companies are mere systems integrators:

If you were to go buy a premium German electric car, the engineers who designed the drive inverter in that car, they did not work for that car company, they worked for a contractor. And at Tesla, we design the entire car and the factory that builds it. - Colin Campbell

In the modern day, the systems integrator approach will never be able to compete with the vertical integration of Tesla. Inferior design, worse performance, supply chain issues, bottlenecks, stifling innovation or a combination of all these things is what you will continue to see with traditional automakers. As they try to catch up to Tesla, Tesla’s culture and organizational structure propel them that much further ahead.

Tesla innovates, vertically integrates and operates in house while others outsource. The importance of Tesla’s approach will become extremely evident in the long term. Looking back it will be painfully obvious to see this should be industry standard, but you can usually only connect the dots when looking back, not looking forward.

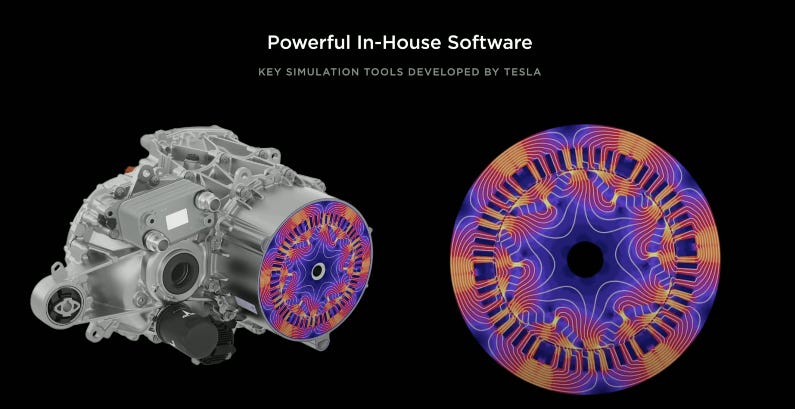

Tesla has done tremendous work not only in hardware, but also in software. As I mentioned in an earlier article, I think the approach of integrating hardware and software effectively will be a dominant business model over the next decade.

One example from the presentation: Tesla has in house software that simulates how a drive unit functions or converts energy into motion. The software allows them to iterate through millions of possible drive units to determine the best design. While other solutions exist, Tesla’s is far more accurate and was difficult to create. This is what continuous innovation looks like. There is no world in which outsourcing all of these seemingly little things leads to a better product.

Yet making the best product is only half the battle. Building it at scale is arguably even more challenging. This is why Tesla keeps it all under one roof. This level of collaboration leads to not only high performance products, but high performance products that are easier to assemble.

Not only will state of the art products continue to be produced, but the efficiency and manufacturing techniques utilized will continue to improve at an even faster rate.

Full Self Driving

Here’s a good chart for the next time the media tells you how unsafe Tesla’s full self driving software is. Humans are bad drivers and when they’re not recording Tik-Toks they’re watching Tik-Toks; unfortunately humans are only becoming more distracted. FSD is still in “Beta” stage so expect this gap to widen as it continuously improves.

Allow me to rant quickly on this topic…

Once you realize:

Legacy automotive companies pay media companies to advertise

+Tesla does not pay to advertise

+ Tesla and Elon Musk are low hanging fruit in the current state of Click Industrial Complex we find ourselves, where media is rewarded by enraging and click baiting to the max as it brings in more revenue

You may start to view their coverage of Tesla differently…

Investing has taught me that if you want an answer, just follow the money and you are sure to find it.

Back to scheduled programming!

Not to mention the other benefit of full self driving: less cars on the road and therefore less power needed. Think of the practical applications that already exist for autonomous cars: people with vision problems at night, the elderly, drunk driving, texting. In the future they will probably ask, “Why did we ever let human beings drive cars at all?!”

Delete, Simplify, Automate

Continuous improvement is central to Tesla. Speed, product design, deployment and cost all continue to improve. This is true from the cars, to the factories that produce them, to the supercharger network where deployment costs as well as per kWh supercharger costs continue to decline.

The number of parts required in the cars continue to decrease. The top 2 vehicles are the Model S and X, which were followed by the 2 vehicles pictured under, the 3 and Y. This leads to declines in both costs and supply chain complexities. This is thanks to incredible design and engineering work, you know, that continuous iteration thing I keep bringing up.

Above is the evolution of the heat pump assembly line.

Tesla discussed so many aspects of the business, I could write at length about all of them, but the same themes were omnipresent: doing more with less, fewer parts, fewer components, less labor, more automation. This is what continuous improvement looks like. I don’t know that any company in history has ever moved as fast as Tesla is moving. Every step of the way they improve and get that much further ahead! It’s not enough they do things that’ve never been done before, then they ask how can we improve this further…

While everyone else is still trying to figure out how to build electric vehicles profitably, Tesla is figuring out how they can apply everything they’ve learned to build 20 million cars a year at exceptional levels of efficiency. Their system is already at work, they need only rinse, repeat and continuously optimize. As long as Tesla continues to iterate, there is no way any auto manufacturer can hope to catch up.

The above chart is a good way to visualize Tesla’s First Principle’s Thinking Approach. The result is continuous improvements in efficiency and time, coupled with a reduction in labor required as well as the number of moving parts. This is how Tesla’s operating margins continue to improve at a seemingly impossible rate, which we’ll get to later.

Tesla Mega Packs

“As you build out the full site, what we end up with is the most energy dense solution on the market… this solution is 2x more power dense than a typical gas peaker plant. This is the future.” - Mike Snyder Senior Director, Megapack, Tesla

“This is the product that retires the fossil fuels.” - Drew Baglino, SVP, Powertrain and Energy Engineering, Tesla

Beyond the precision and efficiency that goes into not only the production of Mega Packs but also their installation, (able to connect to any grid in the world, right out of the box) these 2 quotes summarize Tesla’s efforts to create sustainable energy perfectly. There is a lot more going on under the hood here than cars…

This Is Probably Nothing…

I’ve discussed this many times in the past and while it does not fit into a Wall Street spreadsheet, it is reassuring to see SpaceX and Tesla maintain their top spots as most sought after work destinations for engineering students, year after year. As if Tesla did not already have much of the top tier talent, there is only more on the way.

I don’t think this gets recognized enough. Not only does Tesla make the best, most advanced vehicles on the planet, but they do it with a level of efficiency traditional automakers can only dream of achieving. This translates into many thousands of dollars per car which can either be passed onto the consumer in cost savings and/or added to Tesla’s bottom line profits as their pricing power has demonstrated.

Giga Mexico

Tesla announced a new gigafactory location in Mexico, further diversifying from the 4 existing ones in Fremont (California), Austin (Texas), Berlin (Germany) and Shanghai (China).

I predict Giga Mexico will become the biggest factory the world has ever seen and usher in an age of manufacturing prowess that future generations will marvel at when they read about it in textbooks.

The Big 3

I couldn’t help it, someone should frame this.

Closing Thoughts

Tesla’s culture, at its core, does the following extremely well: Leverage vertical integration, get the manufacturing and engineering teams in the same room, make decisions quickly and with all stakeholders present. While this is the recipe for success and appears a no brainer, it seems Tesla is the only company actually following this blueprint at the highest level of efficiency

I believe Tesla has reached escape velocity. While it’s folly to predict stock prices in the short term, it may take 5 or even 10 years to truly reflect all this, but what I can tell you is that today, Tesla is fundamentally in the strongest position they’ve ever been. There is no sign of slowing down, in fact they are slamming the accelerator to the floor. They will continue to push the limits of what is possible.

There wasn’t a solution in the market that existed, so we built one ourselves.” -Mike Snyder, Senior Director, Megapack, Tesla

Expect to see this quote play out over and over.

Tesla is still an extremely young company. They continue to move fast and break stuff. This is the fastest way forward; without failure there is no progress. I cannot imagine what this company will accomplish by 2030, but Investor Day reassured me that the long term investment thesis remains intact and the company is firing on all cylinders.

While it gets lost in the short term, continuous innovation and iteration are necessary to create and mass produce state of the art products. It takes years to fully play out. Tesla continues to execute on these fronts and exceptional results are the only logical outcome. Ad astra…

I leave you with this short clip. Until next time!

Love this interview. Trust and culture I so agree with these comments.